KEY POINTS

● TEST HOPS FOR RIPENESS TO ENSURE MAXIMUM OIL CONTENT

● START YOUR MASH BEFORE STARTING TO PICK THE HOPS

● DRY SOME HOPS OF THE SAME VARIETY FOR DRY HOPPING (OPTIONAL)

● YOU WILL NEED 8 TIMES WET HOPS COMPARED TO THE AMOUNT YOU WOULD NORMALLY USE WITH DRY HOPS

Every year between the end of September & the middle of October, just after hop harverst in the UK, the Kent Green Hop Beer Festival is held, a celebration of fresh hops for a fortnight where between 30 & 40 Kent breweries exhibit their new Green Hop brews for the harvest season using fresh, or green, Kentish hops instead of hops that have been dried as is more traditional in brewing. The beers have a characteristic fresh taste because the hops used contain many of the oils that are normally lost when hops are dried. The hops are as fresh as can be by using them within 12 hours of being picked. Yakima Valley in the USA has a similar festival.

Fresh hop beer is made from the addition of freshly picked hops (February - March in the Southern Hemisphere) usually from a single variety straight from the hop garden to the kettle. These fresh hops infuse the resulting beer with many of the oils that are unavailable to a brewer using dried hops. Fresh hop beers are among the most satisfying beers in the world.

The secret is always the freshness and oil content of the hops, so as a home brewer and grower of hops, you have a huge advantage over most commercial breweries except for maybe those situated right in a hop growing area or growing their own hops like Sierra Nevada in the USA or the Hop Farm Brewery in Nelson & the Cargo Brewery in Queenstown.

The hops must be picked at their peak of oil production. Unlike alpha acids that remain stable as the hop matures, oils are only produced as the hops near maturity and the percentage of water in the hops is around 22% or preferably less. Once picked the hops literally start to break down and compost so there is a limited time frame to get the best out of your fresh hops. Be aware the over ripe hops will add unwanted flavours to your brew just like over ripe fruit, hence the importance of picking hops at the right time. Most hops will remain at maximum flavour for 3 days and then start to deteriorate.

See our guide Harvesting Hops to determine when is the right time to pick.

After having brewed many fresh hop ales over the years, we find the best course of action is to start your mash and then go and start picking. If you are doing a 20 liter batch then your will need around 450 grams of wet hops split evenly between 2 additions, one at ten minutes before flame out and another after flame out. So you have around 90 - 120 minutes of picking time before you mash out and start the boil.

After sparging and collecting your sweet wort, add your bittering charge as the wort starts to come to the boil. We use around 15g of Magnum pellets. Assuming you do 60 minute boil you now have around another 50 minutes to continue picking more fresh hops if you haven't picked enough already.

Add your 10 minute addition followed by your flame out addition and let them steep for 20 - 45 minutes.

450 grams of wet hops is based on the following:

An average pale ale recipe will have 28 grams of dried flavour hop added at 10 minutes before flame out and 28 grams of dried aroma hops at flame out. But the wet hops are around 80% water whereas the dried hops are around 10% water. So if we multiply 28 grams by 8 we get 224 grams per addition.

Hop varieties we have personally tried that work well for fresh hop beers are Cascade, Mount Hood, Liberty and Tangerine Dream. Some brewers have had great success with Riwaka. Where we live in North Canterbury, Tangerine Dream is usually ready to pick a few days before Cascade. The timing is so close that you could not only make a fresh hop beers from each but also do a brew combining both Cascade and Tangerine Dream.

Stan Hieronymus shares the three keys to brewing successfully with wet hops and the four “rules of hops” that you should understand.

Trevor Holmes, head brewer at Wadworth Brewery in the south of England, surely was not the first to add freshly picked hops to a batch of beer—that likely happened hundreds, maybe even thousands, of years before Holmes made the first batch of Malt ‘n’ Hops in 1992. However, his beer begat the first Sierra Nevada Harvest Ale in 1996, which in turn begat hundreds of beers variously described as wet hopped or fresh hopped.

The two aren’t necessarily the same. Brewers sometimes describe hops right out of a drying kiln as fresh, so “fresh-hops” beers may be brewed with either dried hops or unkilned hops. Wet hops are never kilned. The difference matters in the brewing kettle just as much as in the glass.

The first time Holmes brewed Malt ‘n’ Hops, he expected the 100-barrel batch to last a month. It sold out in a week. The late Michael Jackson described it as having “a surge of cleansing, refreshing, resiny, almost orange-zest flavors; and, finally, an astonishingly late, long finish of fresh, appetite-arousing bitterness.” Sierra Nevada Brewmaster Steve Dresler learned about the beer secondhand, from Gerard Lemmens, a native of England who worked for an American hops broker at the time. Dresler was otherwise left to his own devices, but these days the path is better marked. There are three keys to brewing successfully with wet hops and four “rules of hops” that you should understand.

What You Really Need to Know

» Wet hops truly are wet

Water accounts for about 80 percent of the weight of unkilned hops cones and 10 percent of dried hops. That’s why most brewers add five to eight times, measured by weight, more wet hops than they would dry. The wet hops will take up more room in the kettle, not five times more, but enough to consider reducing the batch size. They’ll also add water that needs to be considered when calculating final gravities. To brew HopTime Harvest Ale, Vinnie Cilurzo at Russian River Brewing makes three hops additions: at the beginning of a 90-minute boil, with 30 minutes to go, and at the end. He knows he’s on track to hit his target gravity when the reading with 30 minutes to go matches his final target because the last two hops additions will contain as much moisture as will evaporate in 30 minutes.

» Fresh matters

Because cones contain such a high percentage of water, they literally begin to rot shortly after they are picked, which is why farmers transport them directly from the field to drying kilns. They generally must be dried or added to a batch of beer within 24 to 48 hours after they are picked. Brewers in the Northwest, located close to the farms where most of America’s hops are grown, often dispatch their own trucks to collect freshly harvested hops. Back at the brewery, another crew will start the mash based upon when they expect the hops to arrive. Brewers elsewhere may have hops shipped overnight. YCH HOPS expects to sell about 20 tons of “Green Hops” during the 2015 harvest, shipping them across the United States, including to Alaska and Hawaii. The resurgence in hops growing outside the Northwest has made it easier for commercial brewers and homebrewers to find locally grown fresh hops. And of course, some commercial brewers and homebrewers simply grow their own.

» It is possible to use too much

There’s a point of saturation at which “grassy” is no longer a positive attribute, and the experience becomes more like chewing on green leaves. “I really want the aroma. The freshness is what it’s about,” Sierra Nevada’s Dresler says. “If you try to drive up the bitterness [by adding more wet hops], you’ll start to get those grassy notes, chlorophylly.” That’s one reason to consider using dried hops, including in pellet form, for the bittering addition. It not only reduces the hops load in the kettle, but it also provides a known source of alpha acids. Another reason to use dry hops for bittering is that home growers can only guess how much bitterness the hops from their backyards may add.

Four “Rules of Hops”

» Hops Chemistry before the Kettle

The aromas and flavors from wet hops that brewers covet are products of essential oils that increase dramatically throughout the weeks before harvest and will continue to change even after hops are dried and stored in bales. During the 2013 harvest, Sierra Nevada measured the essential oil content of early harvested Cascade hops at 0.3–0.7 percent, while hops picked three to four days later contained 0.7–1 percent and smelled more floral. Cascade picked at mid-harvest had 1–1.5 percent oils, and mid- to late-harvest hops 1.5–2 percent. Those were more floral, with citrus and emerging pine notes. Cascades picked two and a half weeks after the first hops had up to 3 percent oil. At their best, they had pleasant herbal and woody aromas but sometimes less pleasant onion and garlic character.

Research at Oregon State University has shown that not only does the amount of oil change, but so does the composition. Unfortunately, there are no studies comparing the differences between wet hops and those that have been kilned. “This is not a scientific exploration of brewing,” says Ninkasi Brewing Cofounder Jamie Floyd, who brews multiple wet-hops beers each harvest. “Where’s the economic benefit of analyzing a beer made once a year?”

» Hops Chemistry in the Kettle

Boiling triggers many of hops’ positive attributes, but it also removes oil. Brewers concerned with adding a known amount of bitterness to beer may choose to use dried hops with measured alpha acids during the boil. Those concerned with preserving oils—and that is much of the point of wet-hopped beers—should remember that a study in Japan found that boiling only 10 minutes drives off half of valuable compounds such as linalool and gernaniol. That’s why many brewers choose to add wet hops only at flameout or in a hops stand (whirlpool hopping).

» Hops Chemistry during Fermentation and Dry Hopping

Hops scientists agree that more research is needed on the biotransformations of hops compounds that occur in the presence of yeast, but recent studies prove that new ones are certainly created. That’s another reason to expect the aromas in wet-hopped beers to differ from those made with kilned hops and also why brewers should not expect a wet-hopped beer to smell just like hops picked directly off the bine. “When I taste it the first 12 or 24 hours [into fermentation], all I get is chlorophyll,” says Jeremy Marshall at Lagunitas Brewing. “The first time we made [a wet-hopped beer], it tasted like a cigar. I almost dropped a batch because of the cigar taste. Then it starts to open up; the oils go through.”

» Hops Chemistry in the Package

John Harris at Ecliptic Brewing in Portland, Oregon, does not favor bottling fresh-hopped beers. “I think they fall apart too fast to put them in the bottle. In a month they are a different beer,” he says. However, there is no reason that the aromas from wet-hopped beers would be any more ephemeral than any other hops aromas. Tom Nielsen, manager of Raw Material Development and Quality at Sierra Nevada, points out that poor oxygen control in the bottling process will injure any hoppy beer and that crown liners may scalp aroma. However, he wrote in an email, “Our harvest ales hold up exceedingly well in the bottle—probably some of the best storing beer we make.” Because they taste fresh.

20 LITERS | ABV 4.3 | IBU ~32 | SRM 4.5 | MASH EFFICIENCY 75% | PRE BOIL 24L | OG 1.042 | FG 1.010

MASH 90 MIN @ 67⁰C | BOIL 60 MIN

NOTES:

• YOU CAN SUBSTITUTE CASCADE WITH YOUR FAVORITE FRESH HOP

MASH:

• 3250g MARIS OTTER ALE MALT 3.0 SRM [90.6%]

• 112g WHEAT MALT 2.1 SRM [3.1%]

• 122g AROMATIC MALT 30.5 SRM [3.1%]

• 56g CARAMALT 30 SRM [1.6%]

BOIL:

• 14g MAGNUM PELLETS 12% AA @ 60 MINUTES

• 224g WET CASCADE 5.5% AA @ 10 MINUTES

STEEP/WHIRLPOOL HOPS FOR 30 MINUTES - START @ 90⁰C:

• 224g WET CASCADE 5.5% AA

• 1ST CHOICE:

FERMENTIS SAFALE S04

• 2ND CHOICE:

WLP 007 DRY ENGLISH ALE YEAST

ADD 15 MINS BEFORE FLAME OUT:

• 1/4 TSP IRISH MOSS (or clarifier of choice)

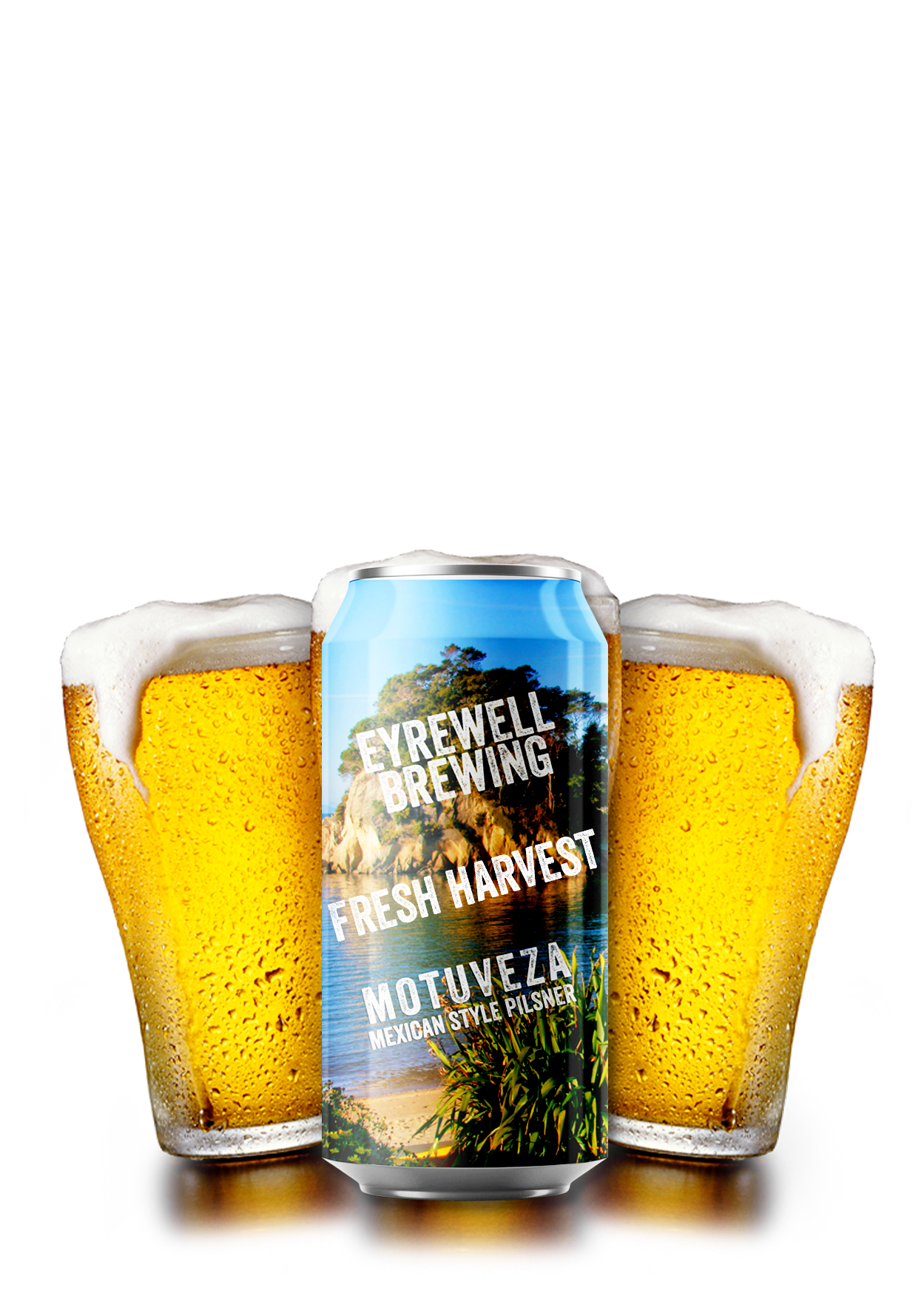

20 LITERS | ABV 5.0% | IBU ~25 | SRM 3.2 | MASH EFFICIENCY 75% | PRE BOIL 24L | OG 1.050 | FG 1.012

MASH 90 MIN @ 66⁰C | BOIL 90 MIN

NOTES:

MASH:

• 3000g PILSNER MALT 1.5 SRM

• 900g FLAKED CORN 1.3 SRM

• 56g MELANOIDEN MALT 20 SRM

BOIL:

• 448g RICE SYRUP 7.0 SRM

• 7g MAGNUM 12% AA @ 60 MINUTES

• 224g WET MOTUEKA 7% AA @ 10 MINUTES

STEEP/WHIRLPOOL 30 MINS @ 90⁰C:

• 224g WET MOTUEKA 7% AA

OPTIONAL: DRY HOP 3 DAYS BEFORE PACKAGING:

• 28g MOTUEKA PELLETS (OR DRIED MOTUEKA CONES)

• 1ST CHOICE: WLP 940 MEXICAN LAGER

• 2ND CHOICE: SAFLAGER W-34/70

ADD 15 MINS BEFORE FLAME OUT:

• 1/4 TSP IRISH MOSS (or clarifier of choice)

20 LITERS | ABV 6.8 | IBU ~65 | SRM 10.2 | MASH EFFICIENCY 75% | PRE BOIL 24L | OG 1.064| FG 1.012

MASH 90 MIN @ 67⁰C | BOIL 60 MIN

NOTES:

• YOU CAN SUBSTITUTE CASCADE WITH YOUR FAVORITE FRESH HOP

MASH:

• 4840g 2 ROW ALE MALT 3.0 SRM [88%]

• 660g LIGHT CRYSTAL ~30 SRM [12%]

BOIL:

• 36g MAGNUM PELLETS 12% AA @ 60 MINUTES

• 224g FRESH CASCADE ~7% AA @ 20 MINUTES

STEEP/WHIRLPOOL HOPS FOR 30 MINUTES - START @ 90⁰C:

• 224g CASCADE 5.5% AA

• 1ST CHOICE: WLP 001 CALIFORNIA ALE

• 2ND CHOICE: WLP O90 SAN DIEGO SUPER YEAST

• 3RD CHOICE: SAFALE US05

ADD 15 MINS BEFORE FLAME OUT:

• 1/4 TSP IRISH MOSS (or clarifier of choice)

20 LITERS | ABV 4.5 | IBU ~32 | SRM 8.2 | MASH EFFICIENCY 75% | PRE BOIL 24L | OG 1.045 | FG 1.011

MASH 90 MIN @ 67°C | BOIL 60 MIN

NOTES:

• YOU CAN SUBSTITUTE KENT GOLDING WITH YOUR FAVORITE FRESH HOP

MASH:

• 3300g ALE MALT 3 SRM

• 224g BISCUIT MALT 30.5 SRM

• 224g MEDIUM CRYSTAL MALT 56.3 SRM

• 224g WHEAT MALT 2.1 SRM

• 14g ROASTED BARLEY 2.1 SRM

BOIL:

• 18g CHALLENGER PELLET 7.5% AA @ 60 MINUTES

• 224g WET KENT GOLDING 5% AA @ 10 MINUTES

STEEP/WHIRLPOOL START @ 90°C FOR 30 MINS:

• 224g WET KENT GOLDING 5% AA

OPTIONAL: DRY HOP FOR 3 DAYS AFTER FERMENTATION HAS FINISHED :

• 28g DRIED GOLDING CONES OR PELLETS

• 1ST CHOICE:

WLP 007 DRY ENGLISH ALE YEAST

ADD 15 MINS BEFORE FLAME OUT:

• 1/4 TSP IRISH MOSS (or clarifier of choice)

20 LITERS | ABV 5.0 | IBU 31 | SRM 7.1 | MASH EFFICIENCY 75% | PRE BOIL 24L | OG 1.047 | FG 1.010

MASH 90 MIN @ 67°C | BOIL 60 MIN

NOTES:

MASH:

• 3250g ALE MALT 2.5 SRM

• 448g MUNICH MALT 8 SRM

• 112g LIGHT CRYSTAL MALT 32 SRM

BOIL:

• 7g MAGNUM 12% AA @ 60 MINUTES

• 224g WET TANGERINE DREAM® CONES 11-12% AA @ 10 MINUTES

STEEP/WHIRLPOOL START @ 90°C FOR 30 MINS:

• 224g WET TANGERINE DREAM® 11-12% AA

(OPTIONAL)

• DRY HOP WITH 56g DRIED TANGERINE DREAM® FOR 3 DAYS BEFORE PACKAGING

• 1ST CHOICE: WLP 090 SAN DIEGO SUPER YEAST

• 2ND CHOICE: WLP 001 CALIFORNIA ALE

ADD 15 MINS BEFORE FLAME OUT:

• 1/4 TSP IRISH MOSS (or clarifier of choice)

INSTANT DOWNLOAD PDF

HAZY IPA | LAGER & PILSNER | BELGIAN & FRENCH ALES | FRESH HOP HARVEST BEER | UK ALES | USA IPA